Orr is quoted on p. 38 in a sidebar focused specifically on machine learning and AI. He notes that AI can be applied to all kinds of circumstances and predicts that new applications will continue to develop. “If you’re motivated to automate a problem, there is a way to do it,” he tells Dodge.

In today’s marketplace, larger contractors are increasingly aware of these benefits and typically maintain a budget for R&D related to construction tech and analytics. For smaller contractors, though, there’s a lot of room for further evolution. “I personally believe that BIM and related technologies will be a key component to helping small- to mid-size contractors grow,” Orr says. “Dodge’s survey results, by quantifying some of the benefits contractors are already reaping, bolster that view.”

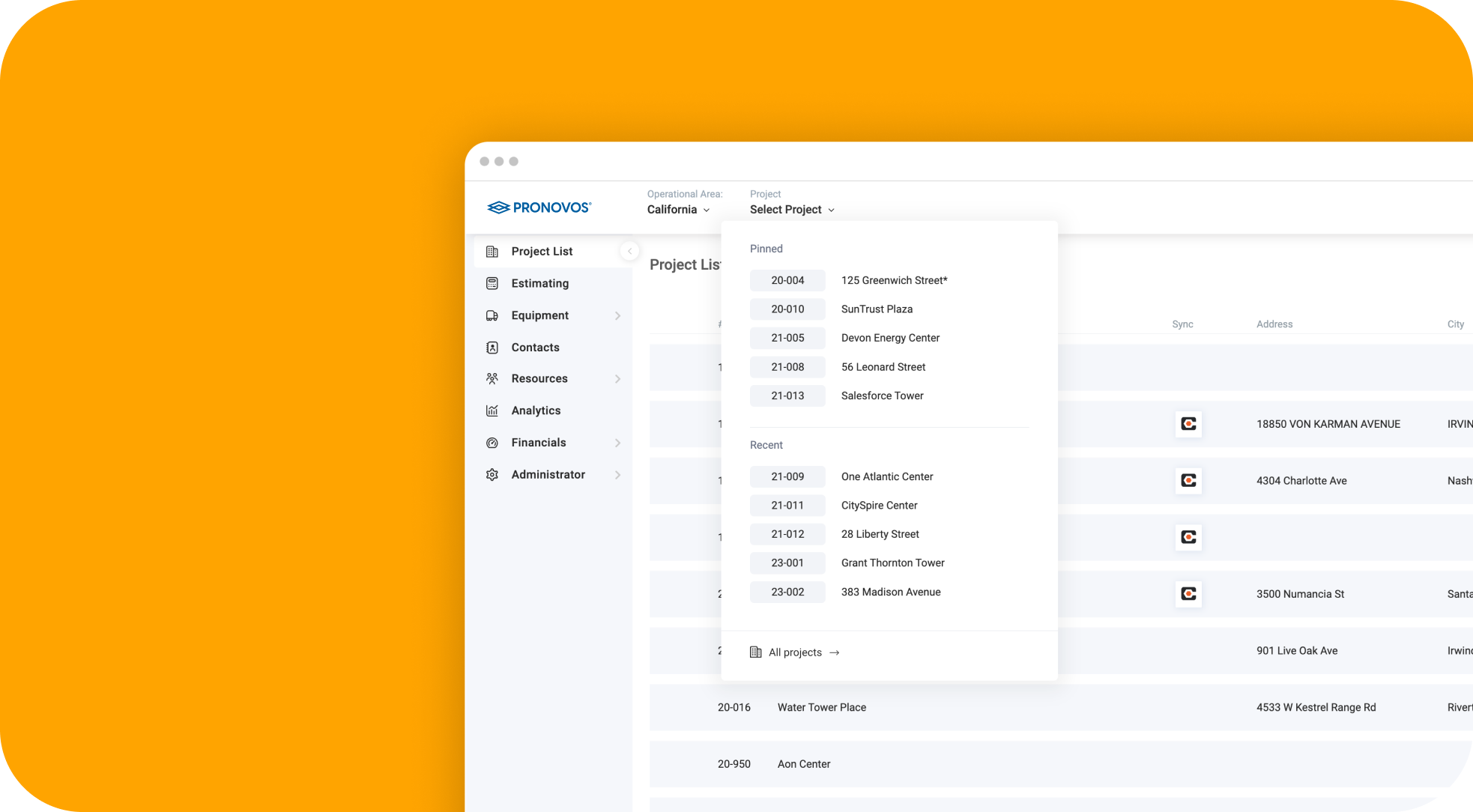

The key is to see the long game and, in some cases, overcome resistance to change. As Orr tells it, some contractors have yet to embrace tech and continue to rely on legacy approaches that are less efficient. “Modern, nimble technology with open APIs allows data to flow between systems,” he notes.

In some cases, the resistance owes to an incorrect assumption that new solutions are always too expensive. “That’s part of the reason we make pricing so transparent in our Analytics Essentials Package.”

Overall, the data scientist is enthusiastic about the industry changes that Dodge Data & Analytics continues to document so skillfully. Contractors, he says, have been producing and sitting on mountains of data without leveraging the benefits.

“AI can take this data and perform tasks that it normally takes multiple personnel to do,” he said. “Let’s take contract review as an example. We have technology that will read every contract, highlight key language that deviates from the norm, or from what you specify, and reduce your contract-review time by up to 75 percent.”

Similar efficiencies can be gained in areas such as drawings, labor-reporting, equipment-tracking, cost projections, quantities and more. “I could take an hour to manually list all of these possibilities,” Orr said, “but come to think of it, maybe I should automate that process.”